Mesa Trim Installation: Architectural Finishing for Desert Homes

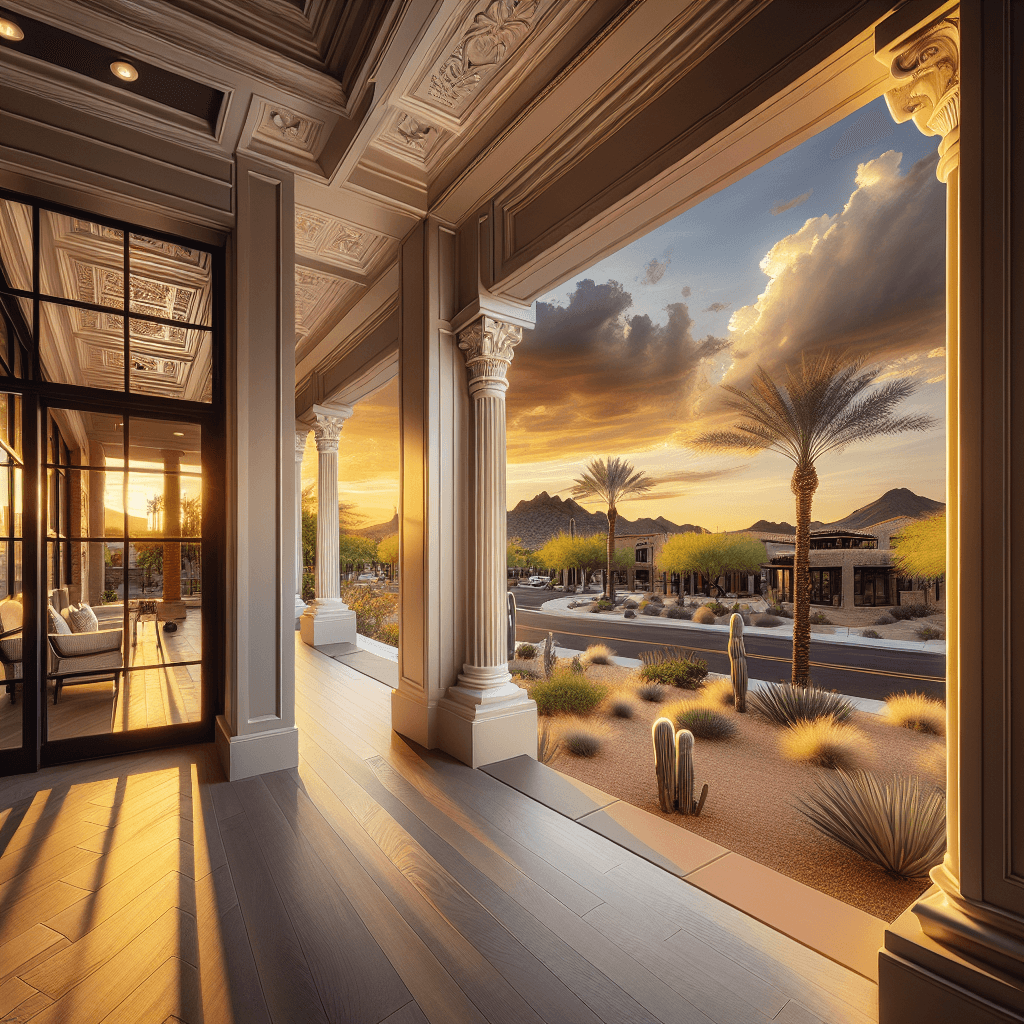

Trim carpentry transforms unfinished window and door openings into polished architectural features. In Mesa's diverse residential landscape—from Eastmark's contemporary designs to Las Sendas Mediterranean estates—trim profiles define interior character while solving practical concerns. Baseboards protect drywall from vacuum bumps and furniture scuffs. Window casings conceal framing gaps and provide mounting surfaces for blinds and curtains. Crown molding creates visual transitions between walls and ceilings, adding depth to rooms with standard 8-foot or vaulted 12-foot ceiling heights.

Material selection balances aesthetics, budget, and Mesa's climate. MDF (medium-density fiberboard) offers dimensional stability in desert heat—no expansion during monsoon humidity spikes, no contraction during winter dry periods. Smooth factory surfaces accept paint flawlessly, and moisture-resistant formulations resist bathroom steam or kitchen humidity better than solid wood. Pine and poplar provide traditional wood grain for stain-grade applications where natural wood character is desired. Hardwoods (oak, maple, cherry) serve luxury estates with premium finishes. Composite exterior trim withstands UV exposure and temperature extremes (25°F to 118°F annual range) without rot or insect damage.

WindowsDoorsNearMe.com approaches trim installations with attention to precision joinery—miter joints cut at exact 45-degree angles, coped inside corners for baseboard runs that accommodate wall irregularities, and scarf joints for crown molding spans exceeding 16-foot board lengths. We coordinate with Mesa's building inspection requirements (trim work generally requires permits only when paired with structural modifications), match existing profiles in partial-room projects, and deliver paint-ready finishes that save homeowners time and labor costs.

- ▹MDF vs solid wood: MDF costs 30-40% less, never splits when nailed near edges, and holds paint better (no wood grain telegraphing through finish coats).

- ▹Profile varieties: baseboards range from simple 3-inch flat stock to elaborate 8-inch Colonial profiles with cap molding and shoe base combinations.

- ▹Crown molding angles: standard 52/38-degree spring angle (most common), 45/45-degree (contemporary), or custom angles for vaulted ceilings and angled walls.

- ▹Finishing options: paint-ready white primer (standard), pre-primed gray (hides imperfections), or pre-finished white (no painting required, scuff-resistant factory coating).